Micro optical beam splitters work with the same principle that beam splitters use. This Micro Optical Beam Splitter can split light or laser into 2 Optical Beam parts. These beams are been reflected exactly at an angle of 45°(45 degrees), just as an optical mirror reflects with the remaining light beam being reflected in a direction of 0°. These Micro Optical Beam splitters are used in useful areas which shows how important they are.

Application Of Micro Optical Beam Splitter

The micro optical beam splitters have been employed in various areas like in the Optical reference measurement systems which involve a measurements system that involves a non-contact measurement using various light sources. Unlike other measurement systems that deploy the use of tactical measurement systems like touch probes, it uses either a point of reference or a computer to calculate the edge detection. It is also applied in laser beam splitters used in optical benches, semi-transparent mirrors for interferometers, splitting or merging of optical beam paths, it’s also used as a divider mirror for imaging application, front surface optical mirrors. Optical measurement systems which appear to be one of the most used parts of it, laser beam combiners, as a beam splitter plate in an optical instrument, in photonics researches, machine vision and image processing, optical fiber application, and lastly in sensor technology.

Features Of Micro Optical Beam Splitter

It’s is coated with an anti-reflecting agent at its back. It is very reliable as it doesn’t generate a phantom laser beam or double image and also has a metal-free dielectric optical coating. A broadband coating design for random polarization for low light loss and high optical technology.

Optical Beam Splitters

- Cage system fixed optical mount that comes with interchangeable optics, cube and beam splitters options, anodized aluminum construction, and adjustable optical mount

- The Broadband polarizing cube beam splitters which 500:1 ratio, AR coating that allows less than 0.5% reflection per surface, a visible and NIR coating

- Lateral Displacement beam splitters, also have a NIR and visible coating which splits incident beam into two parallel beams

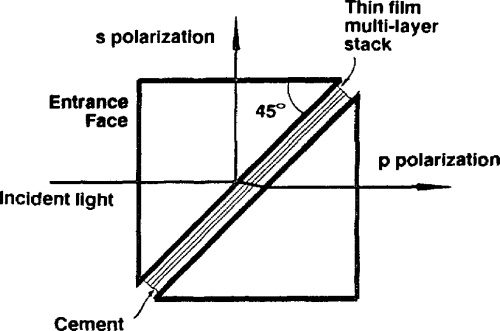

- Laser line polarizing cube beam splitters are designed mainly for diode, gas, and solid-state lasers. It reflects an s-polarized light beam and transmits p-polarized light beam and has a high Extinction ratio

- C-Mounted cube beam splitters that come with female c-mount threaded holes, additional C-Mounted beam splitters, filters, and mirrors. It also has standard and non-polarizing beam splitters

- UV plate beam splitters, which come with a multiple transmission/reflection ratio and a fused silica substrate

- Broadband non-polarizing cube beam splitters have a low polarization dependence with C-Mounted visible and NIR Cube Beam splitters

- Laser line non-polarizing cube beamsplitters have lesser than 3% transmission difference for S and the P-polarization states, an AR coated <0.25% on entrance and exit faces

- Elliptical plate beamsplitters come with a circular profile at 45° visible and NIR coating, ideal for diffuse axial and in-line illumination

- Ultrafast beamsplitters designs for Ti: sapphire and Yb: doped fiber lasers, 90:10, 70:30, and 50:50 (R: T) split ratios, controlled reflection, and transmission GDD

- Fiber optic diffuse axial illuminators with wide-angle, on-axis, diffused illumination, factory hardened, and industrial rugged packages

- Broadband polarizing plate beam splitter has a wire grid technology that reflects S-polarized light, transmits P-polarized light and it’s ideal for high-temperature environments